Using a liquid Loctite Threadlocker on your threaded assemblies will certainly increase their reliability and can secure them against vibration practically forever. Naturally, that may not always be what you want, so it’s important to understand the differences between grades and possibilities they offer.

The first thing you need to do is answer 3 main questions:

- What’s your fastener size?

- Which is the required strength?

- How frequently does the machine / device need to be serviced?

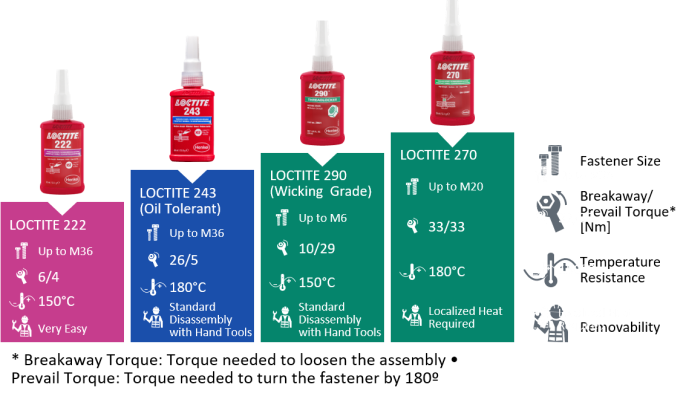

Typically, on smaller size fasteners, lower strength grades like Loctite 222 will work well enough regardless of what kind of vibrational loads they may be subjected to. Also, if you have a high servicing frequency requirement, you’ll want to use a lower strength grade as well.

For assemblies that get dismantled for servicing less frequently (and for bolts larger than M6) a medium strength product Loctite 243 is recommended. Loctite 243 is also oil tolerant and has a higher temperature resistance than Loctite 222 (1800C vs. 1500C).

For threaded assemblies that get disassembled very rarely, the recommended product would be Loctite 270.

It’s also possible to secure a threaded assembly that has already been assembled. For this you can use Loctite 290 which is a product with wicking properties and will creep into the assembly and between the already torqued threads.

There can be a few more factors to consider so it’s definitely recommended you look into our recommendation online or contact our technical customer service if you have any concerns.

One thought on “How to select the right Loctite Threadlocker”